A Dry Chemical Fire Extinguisher is the most common type used in Australia. It is also known as a DCP, BE, or ABE fire extinguisher. To determine if a fire extinguisher is a dry chemical type, one simply needs to look for the white band that runs around the tank. One can also check the description sign to ensure they have a dry chemical fire extinguisher. With this information, people will know more about these extinguishers and how they work so they can be used safely.

Identifying Dry Chemical Powder fire extinguishers | DCP, ABE

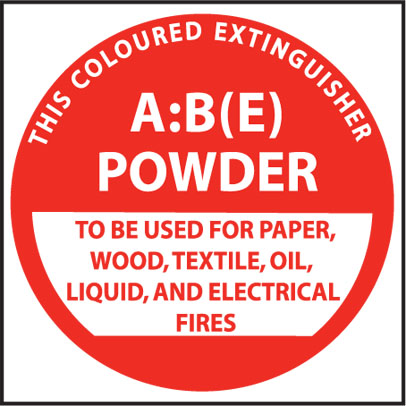

DCP fire extinguishers are easily distinguishable by the white band that is around the fire extinguisher cylinder near the top and if installed in a building they should also be identified by what is known as a description sign, which describes what fires the fire extinguisher can and cannot be used for.

What fires can dry chemical powder fire extinguishers be used on?

As has already been mentioned, dry chemical powder fire extinguishers and extremely effective and versatile.

ABE Type :

- Class A Fires - paper, cardboard, wood, fabrics, people etc.

- Class B Fires - flammable liquid fires, petrol, deisel, oil etc

- Class E Fires - electrical fires, computers, photocopiers, switchboards etc

BE Type:

- Class B Fires - flammable liquid fires, petrol, deisel, oil etc

- Class E Fires - electrical fires, computers, photocopiers, switchboards etc

- Class F Fires - although not included in the rating the BE type is capable of extinguishing cooking oil fires

Both types of dry chemical powder fire extinguishers can be used on flammable gas fires, however evaluate the situation carefully before doing this, as burning gas eliminates the gas, whereas if the fire is extinguished, the gas can continue to leak, build up and become a potential bomb if ignition is triggered.

How Does a Dry Powder Chemical Extinguisher Work?

Each type of extinguisher works by attempting to remove one of the elements that are needed for a fire to flourish. Most ABE extinguishers are filled with monoammonium phosphate which has the ability to flow easily and melt so it continues to cover the flames as it moves over the fire. BE powder does not melt so it is ineffective against class A fires.

ADVANTAGES

- Quick Knockdown - Dry powder, when correctly applied and at the required application rate, has the ability to ensure an initial quick knockdown of the fire.

- Non-Conductor of Electricity - Dry powder can safely be used at incidents where it is known or suspected that ‘live’ electrical equipment is present.

- Good on Running Fuel Fires - Owing to its fire extinguishing action, dry powder, when used in conjunction with foam sprays, can be extremely effective when used on running fuel fires.

- Creates No Thermal Shock - Because the application of dry powder onto hot metal does not cause thermal shock, it is particularly useful for dealing with fires involving undercarriage assemblies.

- Good Heat Shield - The discharge of dry powder creates an effective shield against radiated heat. In cases where large quantities of powder are discharged, this has the potential to shield surrounding structures and personnel from the damaging effects of the fire.

- Wide Range Of Use – Dry powder extinguishers can be used on class A,B and C Fires.

- Wide Temperature Range – Typically can be used between -20oc to +60oc.

- Mass for mass the most effective fire-fighting medium.

DISADVANTAGES

- Visibility Problems - The application of dry powder and generation of a dense powder cloud will dramatically reduce the visibility of the operator so they may not be able to use vision to judge the effectiveness of the powder on the fire or may jeopardise escape in a fire.

- Can Cause Breathing Problems - If dry powder is inhaled it can irritate the respiratory organs. Whilst short term exposure is not considered to be harmful, repeated inhalation should be avoided.

- Leaves a Residue - Dry powder is a very messy extinguishing agent that will leave behind a residue that is corrosive to certain materials and because it is a fine powder it can also be abrasive. Thoughtless use may lead to the powder causing more damage than the fire itself, using dry powder fire extinguishers in kitchens or offices as powder can contaminate food and inhibit the use of electrical components such as keyboards if discharged. Because of the properties of powder being very light and easily carried through the atmosphere dry powder extinguishers when discharged can risk contamination over a wide area.

- Poor Post Fire Security - Due to the smothering and chemical interference effect of dry powder, it will only remain effective whilst it is present in the atmosphere above the fuel. Because it is a cloud of fine powder, particles of it can easily be dispersed by the wind, giving a very real danger of rapid re-ignition of fuel.

- Vulnerable To Packing Down – Failure of extinguisher can result from the packing down of the powder within the extinguisher body, this problem is associated more with cartridge operated extinguishers. This can be a particular problem on vehicle mounted equipment as the vehicle vibration will cause the powder to compress under its own weight. Regular maintenance routines are essential; to prevent failure of equipment at a crucial time.

- Can Break Down Foam Blanket – The use of dry powder close to an area covered by a foam blanket may lead to the foam breaking down more quickly.

- Usage & Location – Because of the disadvantages above dry powder extinguishers should only be found in industrial/residential settings and where no alternative fire extinguisher mediums are suitable.

- Limit of use, not to be used on class D,F fires